story

Ram Pump Lady

“Ram Pump Lady” is becoming my family nickname or “Lady Ram” in the case of one of my grand-nieces, in the Philippines.

There is a very small, section of land there with source of fresh water on the site. Being of an uneven surface, the land has has not been possible to irrigate fully, thus cultivation has not proved possible, on some parts. The people’s income is affected because of the inability to grow better quality crops without an adequate and regular water supply. The area is also “off grid” so there is no mains source of energy. Apart from the cost of a machine and its maintenance and fuel, a petrol driven generator would also present security issues, .for the locals

So…. I decided to research the subject. Essentially, I was looking for a relatively low cost machine, capable of pumping water uphill, night and day indefinitely, with little or no maintenance. It was like looking for a perpetual motion machine. The technology surely did not exist. After some research on the internet, I discovered that the technology had indeed, existed since the 1700s. Over the centuries it had been adapted and improved and it was now possible to use parts available from plumbers merchants to assemble such machines providing the technology was understood. It is called a ………..

“Hydraulic Ram Pump”

wikipedia.org describes such a pump as:

“A hydraulic ram, or hydram, is a cyclic water pump powered by hydropower. It takes in water at one “hydraulic head” (pressure) and flow rate, and outputs water at a higher hydraulic head and lower flow rate. The device uses the water hammer effect to develop pressure that allows a portion of the input water that powers the pump to be lifted to a point higher than where the water originally started. The hydraulic ram is sometimes used in remote areas, where there is both a source of low-head hydropower and a need for pumping water to a destination higher in elevation than the source. In this situation, the ram is often useful, since it requires no outside source of power other than the kinetic energy of flowing water.

Ram pumps are ideal for anyone living in an area without access to electricity because they only require a nearby flowing water source and a slope. No energy other than the weight of the descending water, in a drive pipe, is required. The basic technology has existed for centuries although there have been innovations and improvements over that time. These have often resulted in some patented variations to such pumps resulting in them being quite costly to buy.

It is quite possible, of course, for technically capable people to assemble hydraulic ram pumps themselves, providing they understand the technology and have access to supplies of the component parts. It is also possible for some small farmers to join local groups of similar farmers, to obtain government assistance to purchase a larger pump for community use. AIDFI (Alternative Indigenous Development Foundation) has been manufacturing and installing such ram pumps, throughout the islands of the Philippines, since 2009 and has transformed peoples’ lives, for the better, in the process.

My pumps are being designed for those small farmers and others who do not fit into the above categories. They will come assembled already and will be priced to be much more affordable, once my final design is tested and completed. Because the pumps have only two moving parts and do not need any power other than the energy provided by the weight of the water, they will usually continue to work twenty four hours a day, for many years. Providing care is taken to ensure that the water in-take filter on the drive pipe is fitted with a gauze mesh to prevent the entry of water-borne debris, any maintenance required is minimal.

How do the work?

There are only two moving parts on a ram pump, which are the usually stainless steel, or brass, swing check valve (often called the waste valve) which is normally open and the spring loaded check valve. The weight of the incoming water causes the “waste valve” to close. This then causes higher pressure in the pump and the spring loaded check valve is forced to open. Some of the water then passes through the open spring valve and enters the pressure chamber. Because the waste valve is closed, the remaining water has no-where to go so it heads back up the intake pipe. This creates an area of low pressure which allows the spring check valve to close and the waste valve to open. This process causes the pressure chamber to accumulate air. As the spring check valve is now closed, this air pressure forces the water out of the chamber and into the outlet/delivery pipe. The process then repeats indefinitely.

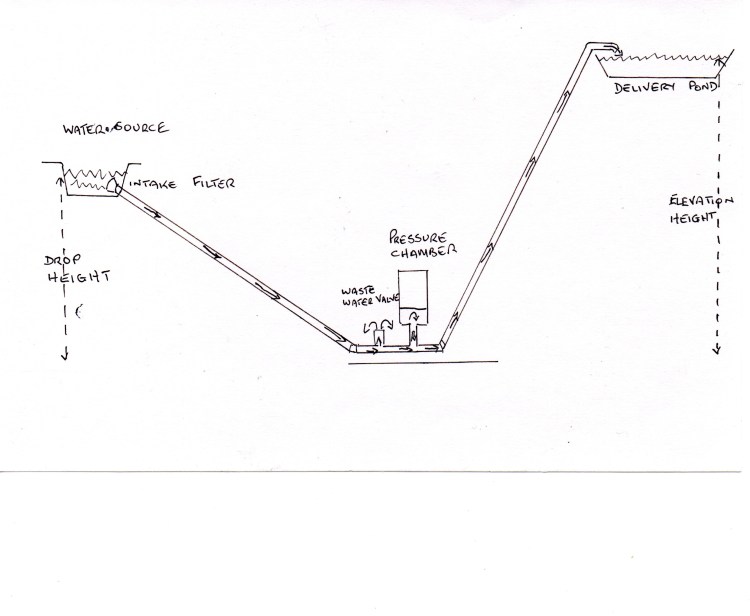

How are they installed?

Installation is a simple process but care must be taken to follow some basic principles. The source of the water supply must be at least 3ft (1metreapprox) above the level of the pump because the down-rushing water in the inlet/drive pipe creates the pressure the pump needs to function. This is called the drop or fall height. The inlet/drive pipe must be fitted with a simple filter screen at its intake end, to prevent small particles of debris from entering and blocking the pump. The inlet pipe and filter must also be kept BELOW the surface of the water source. This is to prevent air from entering the pipe, with the water, which would stop the pump working. The inlet/drive pipe such be a minimum of about 15 feet (5 metres) long. Ideally, it should be rigid and straight and fastened down to prevent “bounce” from the hammer effect of the water, as this could effect the pump efficiency. Some rocks might do the job.

The fall height and intake pipe length will be determined by the height it is wished to pump the water up to. There is a formula which can be used to calculate pipe lengths. These calculations are based on 1 inch pipe being used.

Minimum length inlet pipe. Length = 150 x 1 = 150 inches (12ft 6”) Maximum length inlet pipe Length = 1000 x 1 =1000 inches (83ft apprx)

How do you start them up?

This is a very simple process. They have to be started up only if they have been turned off, apart from the very first time.

1. close the delivery/outlet valve

2. open the inlet valve

3. the swing check valve will close so press it open with your finger until all of the air is pumped out.

4. when it starts, slowly open the delivery valve, a little at a time

5. these steps may have to be repeated several times to get working pressure

It should be remembered that these pumps are first class at doing their job. They work day and night and require no energy input other than the water itself. By their very nature, they are not very efficient but can easily meet the requirements of a small irrigation scheme or household by pumping water up to a holding tank or pond. If the water source is great enough possibly one or more additional ram pumps can be added in a “daisy-chain” to reach an even higher elevation. The water expelled by the “waste pipe” can also be used to create a pond or put to other practical uses. (it is only called “waste” because it is not required by the pump after that point)

Maintenance.

Ram Pumps can function indefinitely with minimal maintenance and expense. However, this depends on the material used.

Stainless Steel, being an alloy is very durable, lasting for many years because it is resistant to rust. (this is the most expensive option)

Brass can destructively corrode depending on the zinc content. (this is the second most expensive option)

Galvanised Steel can corrode if the coating gets damaged. (this is the third most expensive option)

UPVC and PVCu are both corrosion and Ultra Violet resistant. They can also tolerate a temperature up to 60 degrees Centigrade. As our pumps are for use in the tropics, cold weather performance was not part of our research. (this is the most reasonable costing option)

If cost is not an issue, then the stainless steel is the best option.

The brass and galvanised steel are still a good option but because both are vulnerable to corrosion damage, they are less durable.

The UPVC and PVCu is also very good. Being corrosion, UV and high temperature resistant, together with its reasonable cost, it is our favourite for use in the Philippines by provincial farmers on modest incomes.

Because of the constant slamming of the “waste” valve (swing check valve), we preferred to use a foot valve instead, as this would reduce both the slamming and noise and lead to less wear and tear. we were also hoping to use UPVC for both valves. Unfortunately, following trials, it was discovered that the UPVC was not a practical choice for the swing valve, so I have decided that stainless steel remains the best option.

The prototypes are now undergoing testing in the tropical conditions of the Philippines which is expected to last a year, at least. The extended testing period will allow the users to see how the pumps perform in the climate in which they will mainly be intended for and establish their ability to perform, as expected.

You must be logged in to post a comment.