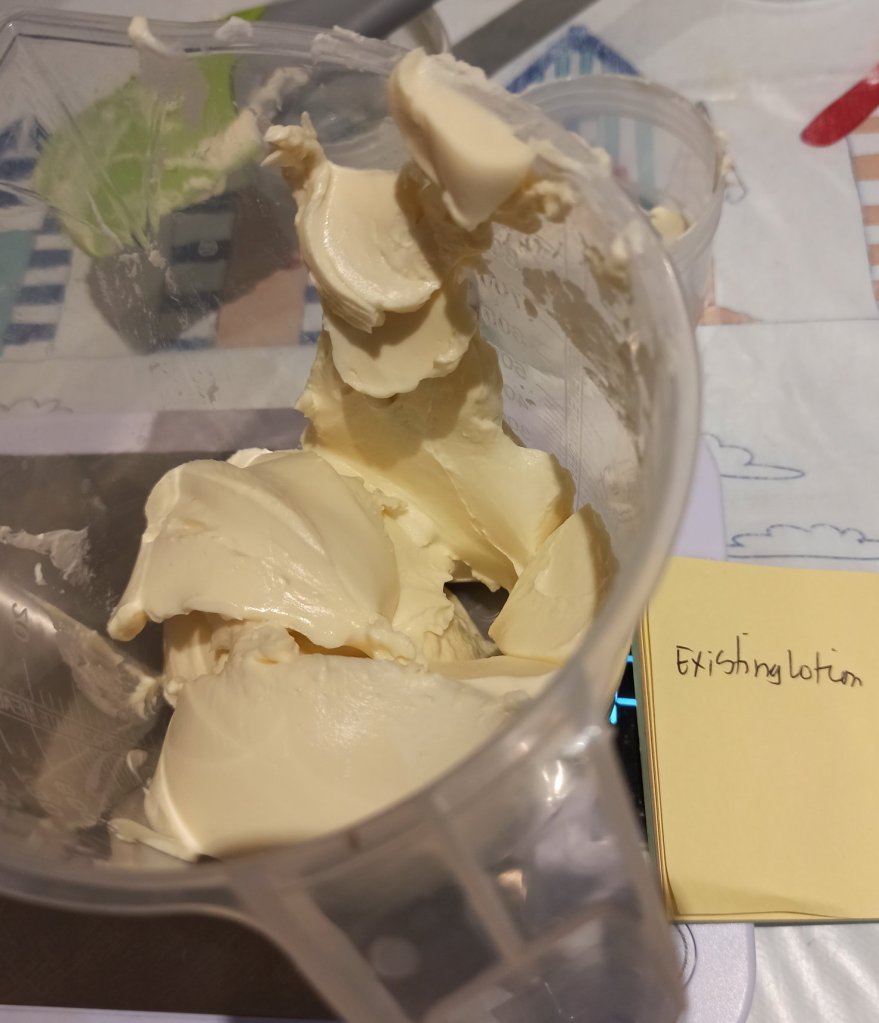

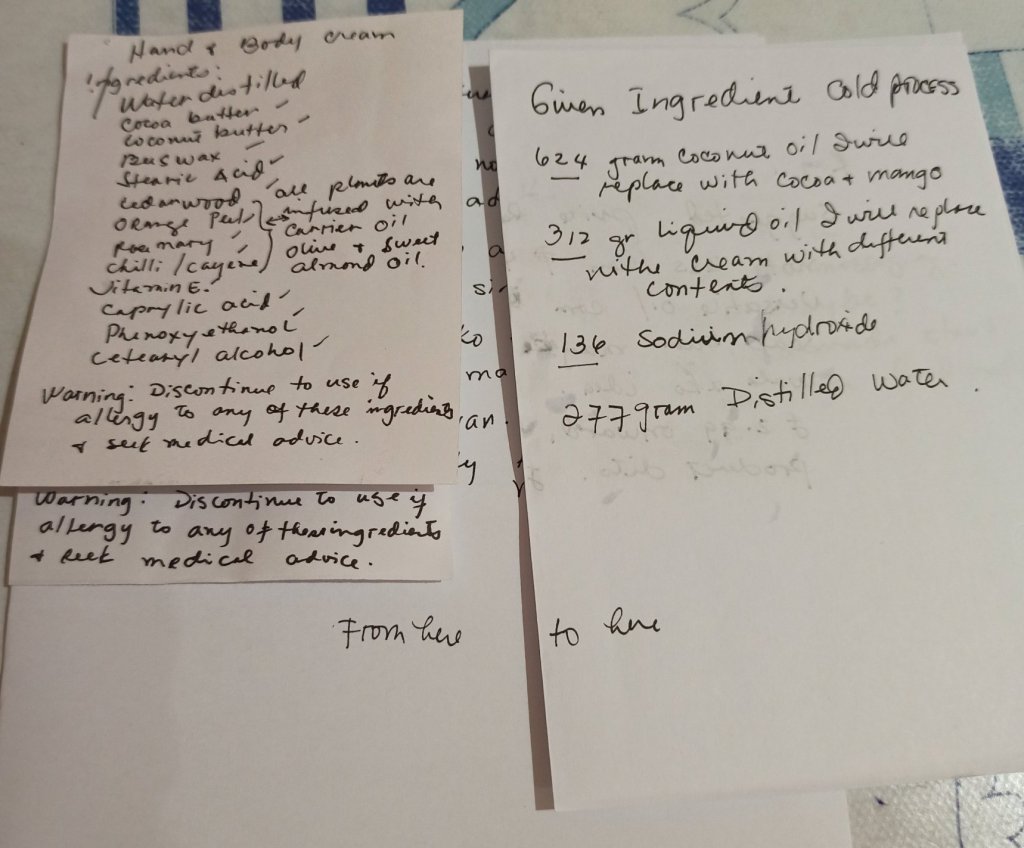

A total fluke. Here below , on the right, are my ingredient measurements for cold process soap. On the left below is the list of ingredients for my existing homemade cream that was too oily for my preference, but otherwise nothing wrong with it though. The cream was made from natural ingredients with a preservative. It just seemed a shame to throw it straight out without utilitising it first, especially as the ingredients were good quality.

A little back ground about the cream. Besides from soap making, I have tried my hands at other crafts too, since their ingredient have similarities and I have plenty of them. It does not make sense to me, to buy small amounts of raw materials that could become expensive. Using the same ingredients, for a spread of items, allows for savings on bulk purchases and also gives me the convenience of always have a stock, to hand. A good example of this is organic coconut oil which is very expensive in retail shops. However, buying from a good quality importer allows me to buy my Filipino oil at a reasonable bulk cost. Unfortunately, the climate here in the UK does not allow me to step into the garden to gather my coconuts for free, as I once could.

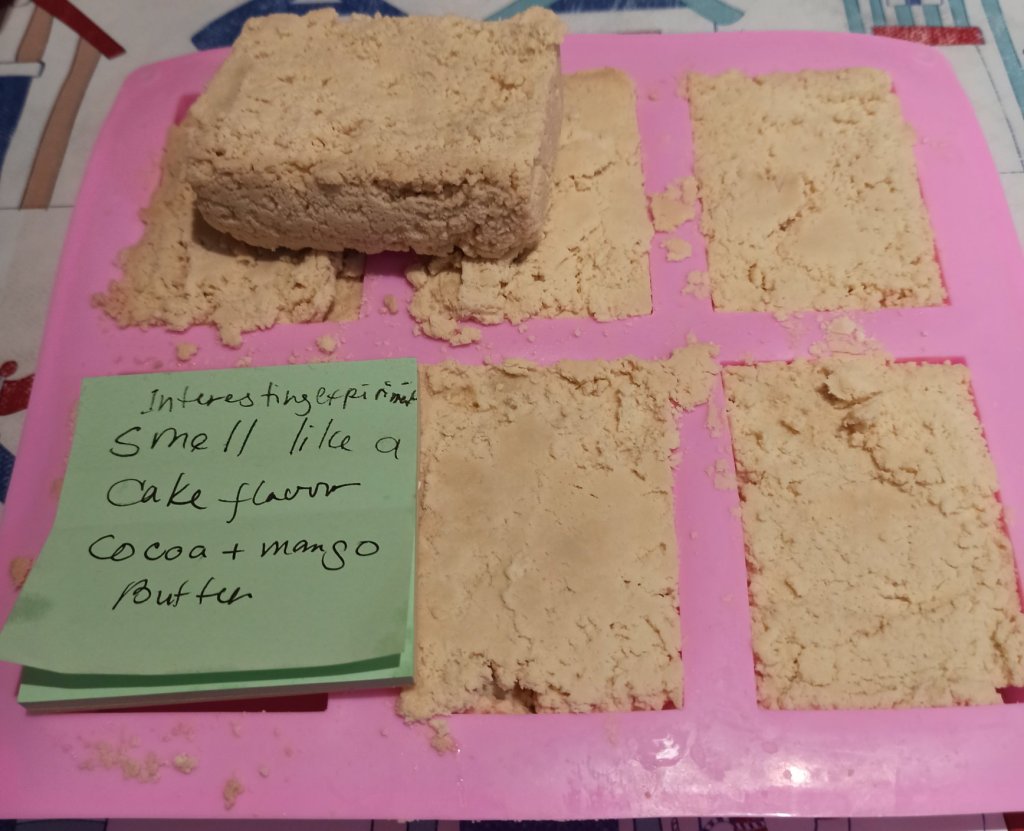

So, I decided to see if I could create a cold pressed soap using the cream as part of the process on the basis that it didn’t matter if this theory does not work because it was otherwise heading for the bin anyway. I still followed the steps in making cold process soap. When I was in the process of mixing the combined cocoa and mango butter it’s emmited a very nice aroma, almost like good enough to eat (not to eat though). I added 50 g of honey and 5g of sodium lactate, to help harden the soap bar, quickly. The batter became watery and I thought what a mess, I’ve made a pig’s ear in here, but I continued the process anyway. I actually wrote it off , and said it to myself it’s just an experiment.

However, I reminded myself too that our forebears have done a lot in this area of making soap and goodness knows what kind of material they’ve used. It reminded me too of Argo soap back home more on this later. (Argo soap is a coarse soap often used for laundry purposes which is made by a South African Chemical company and widely exported) It was definitely not my normal cold process. So I continued the blending and transferred the batter into the moulds, knowing that this would probably be discarded the next day. But wait! don’t throw just yet, it’s actually looks like a pie and the scent is almost too good to eat. I followed my instinct not to throw thing away, unless it is so redundant. I let it sit in the corner, curing, for a few days. After that the bar was dry and hard enough to be tested to see out if it is indeed become a soap? To my surprise, hooray! It is indeed a soap with lots of lather and more gentler to my delicate hands too (joke). Below are the photos I have captured. So that’s my lotion/cream made into soap.

Here is how I did it. I replaced the amount of coconut oil or virgin coconut oil with mango butter and cocoa butter. I did it because I had simply run out of coconut oil and I combined them with my bin bound lotion. I melted the hard butter first and then added the cream and continued the process. In a previous post I already covered the health and safety in making cold process soap. I am very pleased that the outcome has become positive not from Corona virus, but with a soap with lots of lather. This might not look a beauty but who cares, it’s a soap and it will get used and I’m going to enjoy it knowing what the ingredient are it is so satisfiying. I claim victory here to my little experiment. Not a life changing victory though. It’s just fun on my part that I managed to utilize a good cream that otherwise would have been wasted.

Growing up in an island village of the Philippines, life was hard. There is no industy. The main livehood of local folks are fishing and farming for those who have land to till. Supplies of basic necessities are hard to come by. The main supplies come from big cities which we are far away. I remember that, fifty years ago, we could purchase soap bars for a few centavos each. (100 centavos to the Peso and P65 is about One Pound Sterling.) I can’t remember the exact amount it cost. Name of the soap bar was Argo, not to be confused with” Argos” from UK big chain shop. There were other soap bars too, but Argo was the cheapest soap that we could afford. It has a horrible smell, it’s hardly lathered, washing clothes are done by hands until now (exept the well off who can afford the washing machine), we rub and rub the Argo onto our clothes without hardly any lather. In the UK, my husband tells me that there was a similar green soap which was called ” carbolic”. Now I can compare that Argo soap to my experimental soap that I’ve made and mine is far, far so superior in quality. I’m not being arrogant here. My recollection of Argo was rock hard, smelled like pong and it was very poor but lots of good quality of soap are now on the market. Hello to my very own soap brand ” ffletch”, maybe.