This is how I make soap. Its only a small batch, but it is possible to make bigger batches by simply increasing the weights proportionately according to the recipe below.

624 g coconut oil

312 g liquid oil

136 g sodium hydroxide or lye

272 g distilled water

Now I will try to experiment with various oil and butter (mix and match) base on the given weights above.

Please read my previous post for health and safety.

I have mixed coconut oil(hard oil) with cocoa butter(hard). I replaced 100 g of coconut oil with 100 g of cocoa butter. I’ve separately mixed the liquid oils listed below.

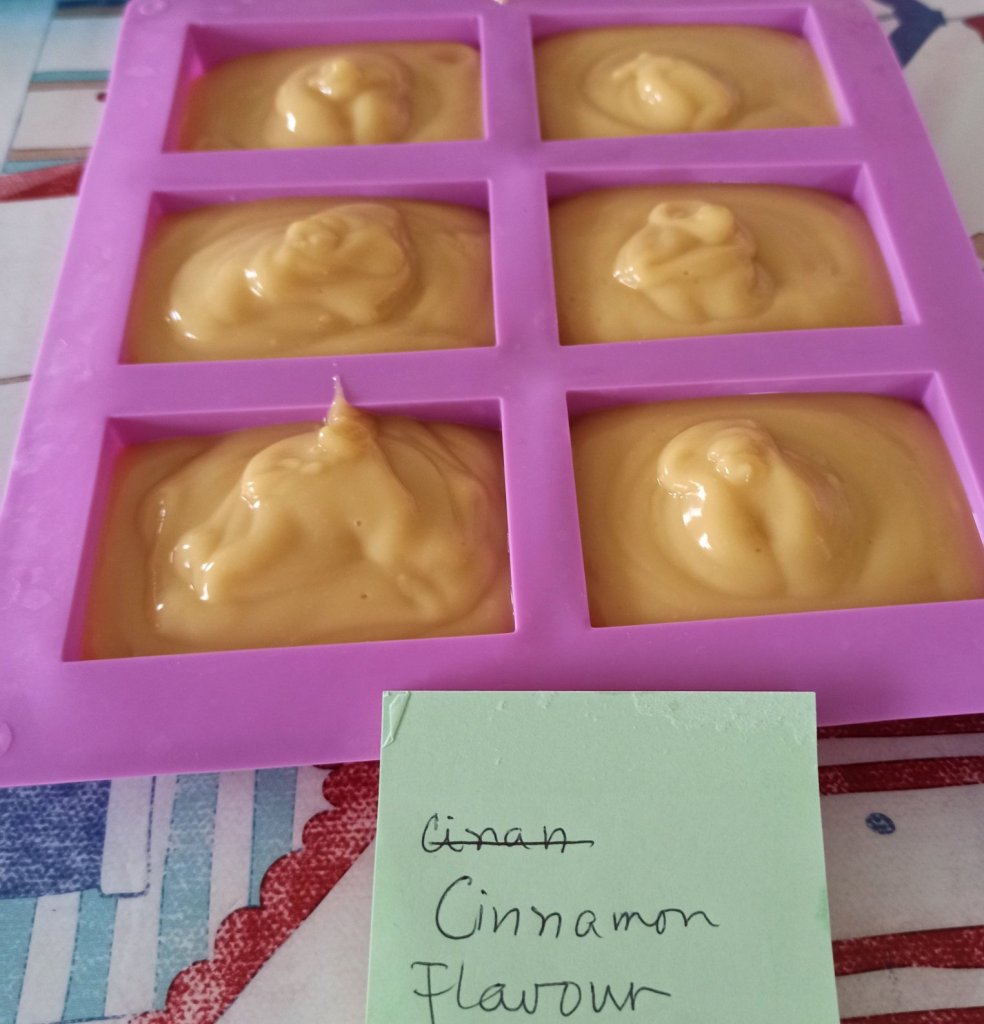

I added the lye solution gently into the melted combined oils. Then using a stick blender with the head under the liquid surface, I began to mix in short bursts of a few seconds each and continued blending until the mixture reached the “trace” stage. In this case I’ve overdid it and made the trace thicker than I intended to.

At this point the mixing is over and now the essential oils and textures can be quicly added. This is the point when artificial colourants and chemical fragrances can be added. (I don’t use any of these)

This mixture is known as “batter”. I then poured the batter into the silicon soap moulds where the soap “cures”. It is usual (not essential) to cover the moulds with an old towel or similar, to insulate the setting mixture, for about twenty four hours. The individual soap bars can then be stored (not stacked) in a well ventilated place for a period of four to six weeks. This allows the soap to fully cure when all the water and lye is evaporated.

And the verdict is so satisfying with lots of lather, though there is only a hint of cinnamon scent.

These are only few days old. It’s best to let them fully cure or harden before using.